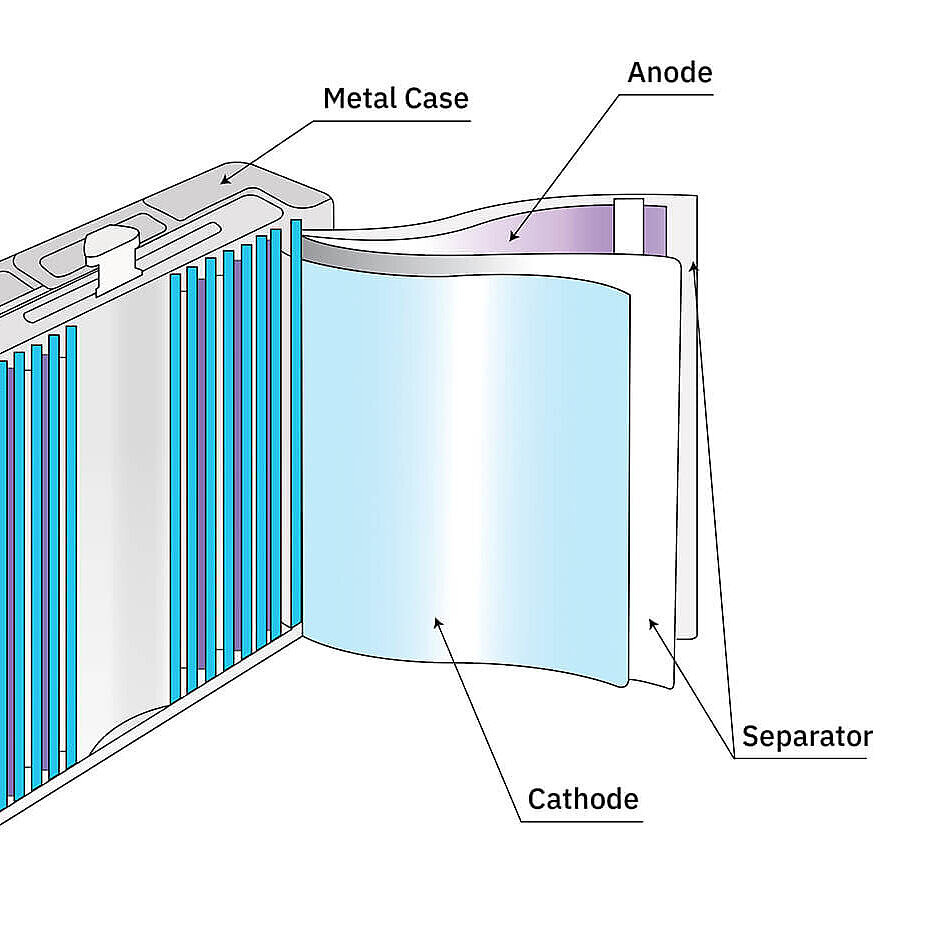

Applications in lithium-ion batteries

Separator coating

Huber Advanced Materials offers a wide range of materials for high-performance separator and electrode coating materials. Fine and narrow particle size distribution (PSD) calcined alumina and alumina trihydrate (ATH) materials with controlled top-cut allow for thin, controlled purity and homogeneous coating layers. Ceramic coating improves safety and assures the reliability of polymeric separator membrane or electrodes, preventing thermal runaway and imparting mechanical strength.

Cathode doping

Huber Advanced Materials offers a range of solutions for Aluminum ion doping of cathode active materials. Their high Aluminum content in powder form eliminates the need for solution, with narrow particle size distribution (PSD) to allow for better processability and sintering. Cutting-edge technology extends the life cycle of high-energy-density, Nickel-rich cathodes through Aluminum doping (NMCA/NCA), bringing added safety and improved performance.

Battery enclosure

Huber Advanced Materials’ fire retardant additives for polymers for used in battery enclosures in electrical vehicles deliver environmentally friendly and halogen-free fire retardants based on highest-quality mineral and organic materials. Several lithium-ion battery components (casing, wires, connectors) are made of polymers that are inherently flammable. Careful selection of fire retardants is essential to meeting safety standards such as UL-94/V0 and ECE R100.

Thermal management

Huber Advanced Materials’ thermally conductive materials fillers for heat dissipation deliver engineered PSD, particle shape and morphology, and surface-treated products. Magnesium hydroxide (MDH), Aluminum hydroxide (ATH) and calcined alumina make it possible to achieve highest filing level (up to 90% weight-%) with balanced cost, processability and physical properties. Thermal management is critical to battery performance. Passive cooling via thermally conductive composites and thermal interface materials (TIM) is the key to assuring reliability.